There is a new kind of metal alloy recently conjured by researchers over at the University of California, Los Angeles (UCLA). It is a new magnesium-based metal that has undergone some nanoparticles tweaking turning it into possibly the strongest alloy metal to date. The alloy promises much application in various industries like aeronautics, space, biomedical and the automotive industries.

The UCLA researchers published their finding in the Nature.com. The new light-weight metal alloy is set to disrupt many industries due to its low-cost commercial viability and high strength. Currently, only titanium and aluminum provides the best strength-to-weight ratio of all commercially viable metal alloys. The UCLA infused silicon carbide nanoparticles with magnesium and came up with a far stronger, lighter and superior metal alloy yet.

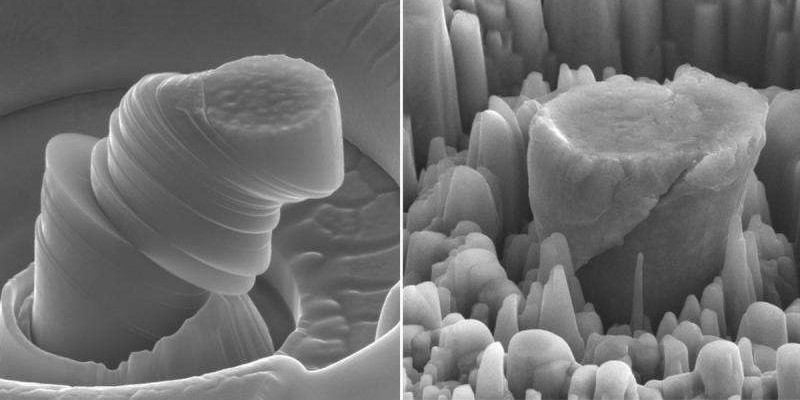

In a nutshell, the UCLA researchers infused silicon carbide nanoparticles into a magnesium-zinc alloy making a new metal that is very strong and still quite light in weight. Silicon carbide is the hard ceramic material that is used in cutting blades. This metal does not change its properties even when heated to high temperatures; something that makes it ideal for many industrial applications.

Magnesium is one element that is abundantly available, and its commercial scale manufacturing is quite a viable venture. Although the research team fell short of revealing just how much it would cost to manufacture the metal on a commercial scale, they, however, did disclose that the alloy is made up 86 percent magnesium and 14 percent silicon carbide.

As cited by Gizmodo report, the UCLA research team said, “In a series of tests, the researchers have shown that, compared to materials with a similar density, it demonstrates ‘record levels’ of stiffness-to-weight ratio and strength-to-weight ratio. The team behind the new material reckons it could be used in aerospace applications, where high strength and light weight are qualities of choice.”

Xiaochun Li, the Principal Investigator on the research and Raytheon Chair in Manufacturing Engineering at UCLA in a statement said, “With an infusion of physics and materials processing, our method paves a new way to enhance the performance of many different kinds of metals by evenly infusing dense nanoparticles to enhance the performance of metals to meet energy and sustainability challenges in today’s society.”

For more information, click here.